AFLAS® FFKM Elastomers

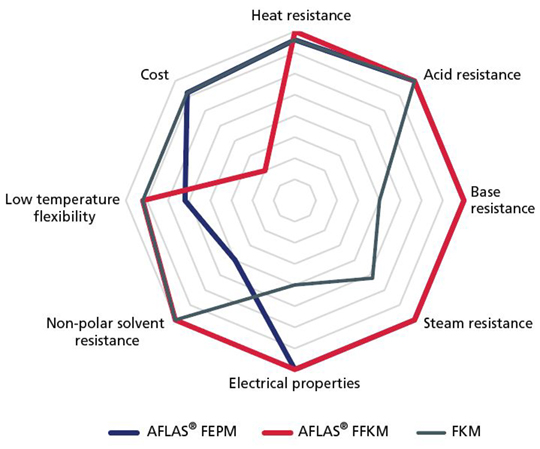

AGC Chemicals Europe has developed AFLAS® FFKM perfluorinated elastomers capable of withstanding very high service temperatures. Being fully fluorinated, FFKM grades exhibit outstanding sealing performance in all manner of aggressive chemical environments. AGC Chemicals Europe continuously develops materials for ever-evolving applications and markets, embracing future challenges.

With their outstanding chemical performance and high temperature capabilities, AFLAS® FFKM grades are perfectly suited for use in O-rings and seals in the harshest conditions.

Features

- Resistant to acid, alkali, steam, oils and solvents

- Continuous operating temperatures up to 300°C

- Retains elasticity due to low compression set

- Exceptional resistance in plasma environments

- Excellent mechanical performance even at higher temperatures

Benefits

- Long life performance in aggressive chemical environments

- Peace of mind for high temperature environments and occasional excursions

- Compressed seals require much less frequent replacement

- Low degradation rate and low particle generation leading to less contamination in process

- Maximum capability in both static and dynamic applications

Grades

AGC Chemicals Europe has developed a range of different AFLAS® FFKM products for various applications depending on the service conditions or other specific needs.

PM-1100: the introduction to FFKM

When FEPM and FKM-type elastomers don’t meet service requirements, PM-1100 is the next level in terms of chemical performance. It is capable of continuously operating at 230°C and at occasional peaks of 250°C. It is the most affordable grade for general applications.

PM-3000: the capable all-rounder

The next level up from PM-1100. This grade has a continuous service temperature of 250°C with peak temperatures around 270°C. With improved compression set, PM-3000 sustains longer pressure periods, reducing maintenance needs.

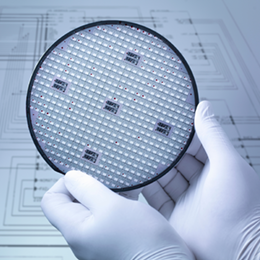

PM-3500: the pure one for demanding applications

Specifically developed for services wherein high-purity is vital to the customer’s processes, PM-3500 is plasma resistant ideal for use in the etching process in semiconductor manufacture. It achieves a Shore A hardness of 70 without the need for fillers that could lead to particulate generation.

PM-5000: the ap-peel-ing one

Utilising a nitrile cure system, PM-5000 will run at 300°C continuously. It has been developed with improved cold compression set and low sticking force.

PM-5500: the high temperature one

Also utilising a nitrile cure system, PM-5500 is capable of continuous operation at 300°C. Shore A hardness of 68 can be achieved without fillers, making it ideal where plasma resistance is required at very high temperatures.

| Grade | Service Temp (°C) |

Compress. Set * (%) |

Chemical Ind. |

Oil & Gas | Semiconductor | Plasma | Comments |

|---|---|---|---|---|---|---|---|

| PM-1100 | 230 | 9.6 | ✔︎ | ✔︎ | Lowest price point | ||

| PM-3000 | 250 | 6 | ✔︎ | ✔︎ | ✔︎ | Versatile; good compression set | |

| PM-3500 | 250 | 17 | ✔︎ | ✔︎ | High hardness with no filler | ||

| PM-5000 | 300 | 12† | ✔︎ | ✔︎ | Low sticking force, improved cool CS | ||

| PM-5500 | 300 | 11† | ✔︎ | ✔︎ | ✔︎ | ✔︎ | High hardness with no filler |

* Compression Set data measured on ASTM Type 1 Button, 70h, 200°C

† Compression Set data measured on JIS B 2401, P-26 O-ring, 25% compression, 70h, 250°C

All of the above grades are peroxide curable for ease of handling and processing. The AGC Chemicals Europe R&D team is constantly looking at ways to improve product offerings in order to push the boundaries of possibility. For any specific requirements or ideas wishing to discuss, please get in touch.