Introducing AGC’s Latest High-Performance AFLAS® FFKM Elastomers: PM-5000 and PM-5500

AGC’s latest advancements in the AFLAS® FFKM series are its cutting-edge elastomers. PM-5000 is the new benchmark for low compression set elastomers, offering low sticking force and exceptional thermal resistance, ideal for O-rings and gaskets in high-temperature settings. It boasts high purity and minimal trace metal content, with impressive resistance to O2 and NF3 plasma, all at a filler-free Shore A hardness of 68.

Elevating the game, PM-5500 inherits all the advantages of PM-5000 but with a superior molecular weight, ensuring even greater performance without the need for fillers, thus minimising particle generation.

Exceptional Heat Resistance for Demanding Applications

The PM-5000 and PM-5500 grades stand out due to their exceptional thermal resistance, making them ideal for high-temperature applications exceeding 300°C. This capability is crucial for semiconductor plasma processes, where maintaining integrity under extreme thermal conditions is essential. These novel grades utilise a nitrile curing system and feature a high molecular weight, achieving increased hardness without the need for fillers.

FFKM: The Ultimate Fluoroelastomer

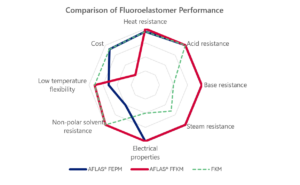

FFKM elastomers represent a significant upgrade over FKM fluoroelastomers. Fully fluorinated, FFKMs excel in high-temperature environments and exhibit superior resistance to chemicals, oils, and solvents. Their mechanical strength, outstanding compression set, and high service temperatures make them the preferred material for manufacturing components that operate under the most demanding conditions.

Components such as seals, O-rings, and other parts made from AFLAS® FFKM demonstrate superior performance and extended service life when compared to those made from FEPM or FKM elastomers. The following chart provides a comprehensive comparison of typical properties among these fluoroelastomers.

Applications in Semiconductor Fabrication Requiring FFKM

The difference between good and great can hinge on the materials used in fabrication. AGC’s AFLAS® FFKM elastomers are here to push your operational excellence.

· Chamber Seals: Ensure an airtight environment for your sensitive processes with seals that offer unmatched durability.

· Wafer Transport Cushioning: Protect your valuable wafers during transport with cushioning that reduces risk and enhances reliability.

· Butterfly Exhaust Valves: Keep your exhaust systems functioning flawlessly with valves that resist the harshest chemicals and temperatures.

· Centring O-Rings in Flanges: Maintain perfect alignment and seal integrity in your flanges with O-rings designed for extreme conditions.

AGC’s Comprehensive AFLAS® FFKM Portfolio for the Semiconductor Sector

AGC’s AFLAS® FFKM elastomers deliver unparalleled performance. Choose PM-1100, PM-3000, and PM-3500 for robust service up to 250°C. When you need something to work hotter, the PM-5000 and PM-5500 grades excel up to 300°C, offering superior plasma and chemical resistance.

Discover the perfect match for your high-stakes applications.

PM-5000: The Benchmark for Low Compression Set

· Low sticking force.

· Exceptional thermal resistance for high-temperature applications, perfect for O-rings and gaskets.

· High purity with minimal trace metals.

· Resistant to O2 and NF3 plasma.

· Filler-free hardness around Shore A 68.

PM-5500: Customized for Superior Molecular Weight

· Inherits all PM-5000 benefits with added higher molecular weight.

· No need for fillers, ensuring low particle generation.

|

Grade |

Service Temp. (°C) |

Compress. Set* (%) |

Storage Modulus (kPa) |

Peroxide |

Nitrile |

Chemical Ind. |

Oil and Gas |

Semiconductor |

Plasma |

Comments |

|

PM-1100 |

230 |

18.1 |

480 |

● |

● |

● |

Peak temperature 250°C |

|||

|

PM-3000 |

250 |

14.3 |

480 |

● |

● |

● |

● |

Versatile; good compression set |

||

|

PM-3500 |

250 |

22 |

450 – 820 |

● |

● |

● |

High hardness with no filler |

|||

|

PM-5000 |

300 |

12† |

200 – 500 |

● |

● |

● |

Low sticking force, improved cool CS |

|||

|

PM-5500 |

300 |

11† |

250 – 550 |

● |

● |

● |

● |

● |

High hardness with no filler |

* Compression Set data measured on JIS-B 2401, P-26 O-ring, 25% compression, 70h, 200°C

† Compression Set data measured on JIS B 2401, P-26 O-ring, 25% compression, 70h, 250°C

FFKM’s Versatility Across Industries

FFKM’s robust properties extend beyond semiconductor applications, making them ideal for use in:

· Chemical Processing due to their exceptional resistance to aggressive chemicals and processes.

· Industrial Equipment because of their high durability against mechanical wear.

· Food Industry as they are compliant with stringent hygiene requirements.

· Pharmaceutical as a result of their capability of meeting rigorous specifications and standards.

AGC’s Commitment to Innovation

Our AFLAS® FFKM PM-5000 and PM-5500 elastomers are nitrile curable, fully fluorinated, and deliver high sealing performance in a large variety of aggressive chemical environments.

AGC is dedicated to developing new AFLAS® FFKM grades to address the evolving needs of emerging applications and markets. Discover our products and find the perfect solution for your requirements.