Fluon® PFA Fluoropolymer

Fluon® PFA (or perfluoroalkoxy) is a fluoropolymer with excellent thermal and chemical resistance.

Fluon® PFA is similar in composition to the fluoropolymers PTFE and FEP (fluorinated ethylene propylene), sharing low coefficient of friction, non-stick properties, and non-reactivity characteristics. Fluon® PFA resists UV light and greatly resists heat with a higher melt strength, therefore enabling use within a temperature range of -200ºC to 260ºC. Furthermore, PFA offers better stability at high processing temperatures and excellent crack and stress resistance whilst maintaining more than ten times the flex life of FEP.

A low dielectric constant allows Fluon® PFA to be used in semiconductor manufacturing and other electrical applications. Its coating is ideal when extended services are required in hostile environments involving chemical, thermal and mechanical stress.

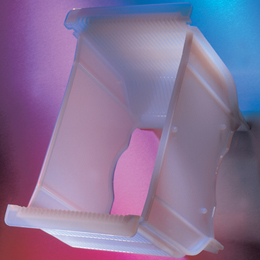

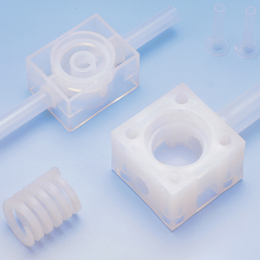

As with other thermoplastic resins, Fluon® PFA can be extruded, injection moulded, blow moulded, and transfer moulded for applications such as tubing, receptacles, lining and wire coating.

| Test Method: |

D3307 | D3418 | D792 | D638 | D638 | ||

|---|---|---|---|---|---|---|---|

| Grade | MFR g/10 Mins | mpt(°c) | S.G. | TS(MPa) | Elong(%) | Processing | Applications |

| P-62XP | 24 – 36 | 305 – 315 | 2.156 | 32 | 410 | Extrusion, Injection moulding | Injection moulding small precision components, wire coating |

| P-63p | 7 – 18 | 305-315 | 2.155 | 32 | 410 | Extrusion, Injection moulding | Wire coating, Injection moulded parts, Tubing |

| P-66p | 1 – 3 | 305-315 | 2.142 | 40 | 340 | Extrusion, Injection moulding, Compression moulding, Blow moulding, Transfer moulding | Components (tubes, valves, rod, sheet, fittings, billets), Stress crack resistant linings |

| EA2000 | 10-30 | 300 | 2.1 | 36 | 460 | Extrusion, Co-extrusion (with PA12 etc.) | Hose & tube, including multi-layer tube, Adhesive film, Printed circuit boards (PCBs) |