Fluon+™ MODIFIERS

Fluon+™ MODIFIERS incorporate functionalised fluoropolymers into existing polymer matrices and composites. Modifiers greatly improve the material’s impact resistance and reduces defects that occur under high-temperature moulding, improving yield.

Modifiers can be applied further to engineered plastics to enhance tolerance against high loads and high temperatures. Modified composites and plastics with fluoropolymers exhibit excellent water absorption, wear resistance, surface protection, low coefficient of friction, flame retardance and more.

Physical properties of PA6 modified by the addition of Fluon+ MODIFIERS

| Physical Properties |

Physical Properties |

Physical Properties |

Physical Properties |

Physical Properties |

|

|---|---|---|---|---|---|

| Modified Plastics | Impact Strength | Tensile Strength | Flexural Strength | Abrasion Quality | Water Absorption |

| Modified-PA6 | Improved↑ | Same→ | Same→ | Improved↑ | Improved↓ |

In testing, physical properties of PA6 modified by the addition of Fluon+™ MODIFERS exhibited improvements in impact strength, abrasion quality, and water absorption, with no negative effects to tensile and flexural strength.

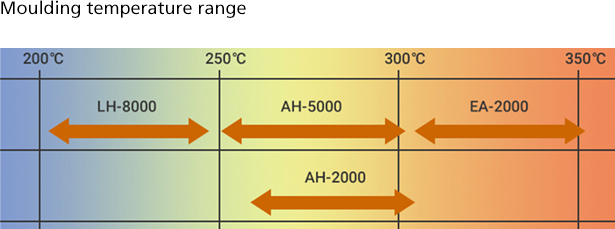

Main Product Types

| Grade | Material | Melting Point |

|---|---|---|

| LH-8000 | ETFE | 190°C |

| AH-5000 | ETFE | 225°C |

| AH-2000 | EFTE | 245°C |

| EA-2000 | PFA | 300°C |

Material modifiers come in the shape of powder or dispersion, with moulding temperature ranges from 19°C to 300°C.