AFLAS® FEPM

AGC Chemicals Europe has developed AFLAS® FEPM grades intended for a new lamination technology for multi-layer hose constructions. These are ideal for use in high-pressure, high-temperature areas around engines where hoses are exposed to nitrogen dioxide (NOx), sulphur dioxide (Sox), engine oils, or other aggressive automotive fluids.

Features

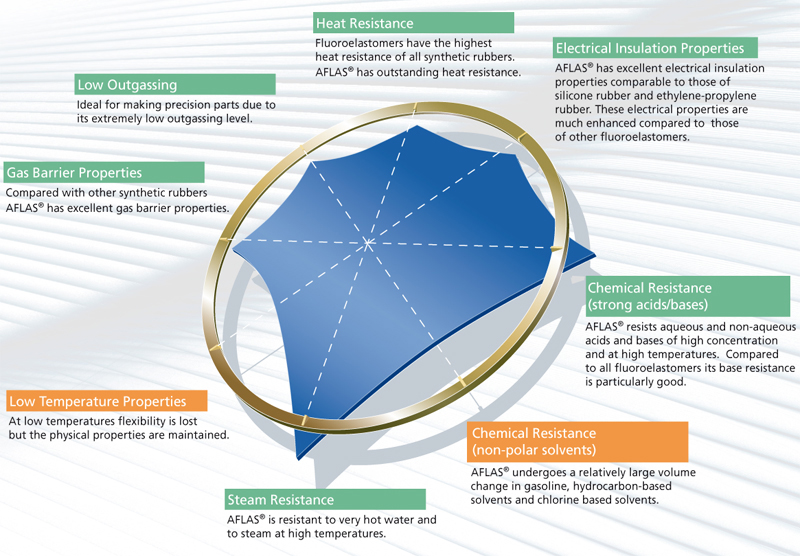

- Heat resistance

- Electrical insulation Properties

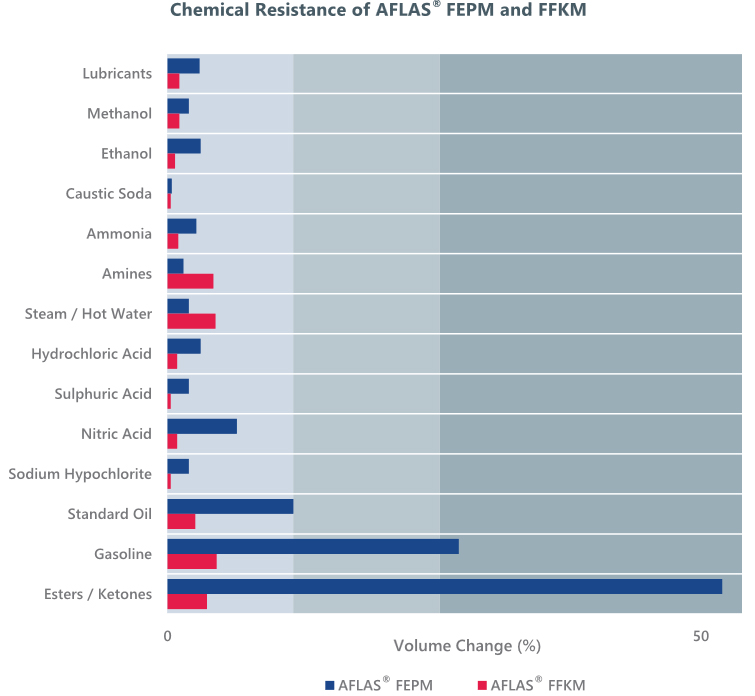

- Chemical resistance (strong acids/bases)

- Chemical resistance (non-polar solvents)

- Steam resistance

- Low temperature properties

- Gas barrier properties

- Low outgassing

Applications

- O-Rings and gaskets

- Manufacture of liquid crystal and semi-conductors

- Wire and cable

- Automotive oil seals

Grades

AFLAS® 100 Series – High molecular weight offers high mechanical strength. Its structure is identical to that of AFLAS® 150. Suitable for compression moulding, transfer moulding, and extrusion.

AFLAS® 150 Series – Excellent at chemical resistance & electrical insulation. Suitable for compression moulding, transfer moulding, and extrusion.

AFLAS® 400E – Comes with new ‘rapid cure’ technology. Colourable, and suitable for extrusion.

AFLAS® 600X – Comes with new ‘rapid cure’ technology. Excellent compression set, tear strength, and improved mould release with a service life of over 25 years. Ideal for high pressure, high temperature (HPHT) applications in harsh environments. Suitable for compression moulding.